JL Audio (ACS112LG-TW1) - Single 12TW1 PowerWedge+ with

DCD Amplifier, Sealed, .25 Ohm

Description:

Amplified Subwoofer System with Single 12TW1-0.25

Subwoofer Driver, Built-In 400W Class D Amplifier, Black

Carpet - Sealed Enclosure

In PowerWedge+ systems, the power is built right into the

subwoofer system. Housing a proprietary Class D

amplifier, this subwoofer system employs JL Audio's

exclusive DCD amplifier technology to extract maximum

output from its specially engineered, ultra low-impedance

TW1 driver. By combining direct power conversion with an

ultra-high current output section, DCD amplifiers are

free of conventional switching power supplies, enabling

them to generate remarkable power with unprecedented

efficiency.

Harnessing the performance and insanely small box

requirements of the TW1 subwoofer driver, this subwoofer

system is designed to deliver amazing sub-bass from an

enclosure that is only 6.625 in. (168 mm) deep. Its

low-profile enclosure design has been carefully

engineered to the optimum sealed enclosure alignment for

the 12TW1 driver and has been fine-tuned through

extensive real-world listening.

Integration to OEM and aftermarket head units is a snap

thanks to a variety of input options and automatic

turn-on capability (via signal sensing or DC offset

sensing). Also included is a variable frequency low-pass

filter (50-200 Hz), along with output polarity control

switch. Adding an optional RBC-1 remote level control

(sold separately) lets you control subwoofer levels

directly from the driver's seat. A quick-disconnect

power connector makes it easy to remove the subwoofer

when you need the extra space.

Note: DCD amplified systems use very specific components.

Never use a DCD amplifier or its companion subwoofer(s)

with incompatible, non-DCD products. Doing so will void

the warranty and may cause severe damage.

Finish: Black, high-grade automotive carpet with silver

"JL AUDIO Built In USA" embroidery on front

baffle. A steel mesh grille is included to protect the

subwoofer driver.

Construction: CNC-Cut High-Grade MDF

Amplifier power: Built-in DCD Class D amplifier (400 W @

0.25 Ohm) Nominal Impedance: 0.25 Ohm

Enclosure and Subwoofer Made in USA

Technology:

DCD Amplifier Technology

The most efficient subwoofer amplifier technology on the

market delivers impressive power with minimal current

draw and heat.

The conventional way to get high power in a car amplifier

is to use a switching power supply. This increases the

battery voltage from its nominal 12V to something

higher-the more powerful the amplifier, the greater the

required voltage. This power conversion is never

perfectly efficient-about 10% of what goes into the

amplifier is wasted and ends up dissipating into heat.

JL Audio's Direct Conversion Class-D Technology (DCD)

innovates by eliminating the need for this power

conversion step entirely. Because JL Audio is still bound

by the laws of physics, the lack of a step-up power

supply means they have to extract as much power as

possible from the vehicle's 12V supply. If JL Audio

were to connect a DCD amplifier to a conventional 4-ohm

subwoofer with this limitation in place, they would only

achieve about 25 watts, and we all know that powering a

subwoofer requires a lot more power than this.

To overcome this obstacle, the DCD amplifiers have been

designed to drive extremely low impedance speaker

loads-as low as 1/4-ohm (0.25 ohm)! With these very low

impedance loads, JL Audio can deliver up to 500 watts of

clean power, subwoofer power. Those who know Ohm's

law and that nothing is free realize that this will

require a lot of current to flow, and that's exactly

what DCD is engineered to deliver...over 50 Amps peak

into a speaker!

To deal with these high current amounts, the special,

very low-impedance JL Audio subwoofer drivers used with

DCD amplifiers are engineered with unique voice coils and

tinsel leads. Connections between the amplifier and

speaker are made using special heavy gauge speaker cable,

with special attention paid to connection integrity to

deal with the high current output.

The benefit of all this effort is that DCD amplifiers

completely avoid the losses associated with a switching

power supply, allowing the entire amplifier to achieve

total power efficiencies in the 91-94% range. This is

very close to the theoretical limit for Class-D

efficiency and results in very little heat being

generated. All of this allows for a very compact,

powerful amplifier that can fit in some of JL Audio's

most space-efficient enclosed systems.

V-Groove MDF Construction

This advanced cabinet-building technique uses

CNC-machining to create precise panel joints that make

enclosure assembly more efficient and exact.

JL Audio begins with quality medium-density fiberboard,

which is then machined on their CNC-controlled KOMO

woodworking stations. These powerful machines are able to

cut a wide range of features onto a sheet of MDF, with

minimal waste and absolute precision. The KOMO machines

cut out the woofer holes, terminal holes, cut dado

grooves, create countersinks and most importantly, cut

the angles at the edges of the panels that form the

enclosure's main shell so that these panels fit

together precisely, with no gaps or leaks.

Once the panels are cut, assembly technicians line them

up in the correct order and glue their outer faces onto a

long piece of carpet, creating a "wrap": a long

series of panels, hinged temporarily by the carpet. In

the next assembly step, their wood assembly teams fill

the V-grooves between the panels and any dado grooves

that receive dividers or secondary wraps with wood-glue.

Once the glue is applied, the enclosure shells folds

together along the V-grooves, capturing dividers in the

dado grooves and secondary wraps, and evenly spreading

the glue throughout the joints. One line of mechanical

fasteners is applied to hold the structure together while

the wood glue dries.

The V-groove technique greatly improves assembly

efficiency, and also results in a far stronger and better

sealed enclosure than the typical butt-joint construction

found on imported enclosures. The quality of the MDF used

in JL Audio systems is also vastly better than the

typical "China-Grade MDF" used in the imported

products.

Dynamic Motor Analysis - DMA Optimized Motor

JL Audio's proprietary Dynamic Motor Analysis system

is a powerful suite of FEA-based modeling systems, first

developed by JL Audio in 1997 and refined over the years

to scientifically address the issue of speaker motor

linearity. This leads to vastly reduced distortion and

faithfully reproduced transients... or put simply: tight,

clean, articulate bass.

Since 1997, JL Audio has been at the forefront of Finite

Element Analysis-based modeling of loudspeaker motors and

suspensions. This research is aimed at decoding what we

refer to as the "Loudspeaker Genome"... a

project aimed at understanding the true behavior of

loudspeakers under power and in motion. A major component

of this integrated system is DMA (Dynamic Motor

Analysis). Starting with the 15W3 and the W7 Subwoofers

in the late 1990's and early 2000's, DMA has

played an important role in the design of all JL Audio

woofers sold today, including their component woofers.

DMA is a Finite Element Analysis (FEA)-based system,

meaning that it takes a large, complex problem, breaks it

down into small solution elements for analysis and then

assembles the data to form an accurate,

"big-picture" solution. DMA's breakthrough

is that it actually considers the effects of power

through the coil as well as coil/cone position within the

framework of a time-domain analysis. This gives them a

highly accurate model of a speaker's actual behavior

under real power, something that the traditional

Thiele-Small models or other low power measurements

cannot do. Because DMA does not rely on a steady-state

model, it is able to consider shifts in the circuit

elements being analyzed. These modeling routines are

intense, requiring hours to run for a whole speaker.

DMA is able to analyze the real effects of fluctuating

power and excursion upon the magnetic circuit of the

motor, specifically the dynamic variations of the

"fixed" magnetic field. This delivers intensely

valuable information compared to traditional modeling,

which assumes that the "fixed" field produced

in the air gap by the magnet and the motor plates is

unchanging. DMA not only shows that this

"fixed" field changes in reaction to the

magnetic field created by current flowing through the

voice coil, but it helps JL Audio's engineers arrive

at motor solutions that minimize this instability.

Analyzing this behavior is critical to understanding the

distortion mechanisms of a speaker motor and sheds light

on the aspects of motor design that determine truly

linear behavior:

- 1. Linear motor force over the speaker's

operational excursion range

- 2. Consistent motor force with both positive and

negative current through the coil

- 3. Consistent motor force at varying applied power

levels

Engineered Lead-Wire System (U.S. Patent

#7,356,157)

Carefully engineered lead-wire design and attachments

ensure controlled, quiet lead-wire behavior under the

most extreme excursion demands.

The payoff is reduced distortion, improved transient

performance and stellar sound quality.

Managing the lead-wires on a long-excursion woofer is one

of the trickier aspects of its mechanical design. To

address this, many long-excursion woofers today rely on a

simple solution that weaves the lead-wires into the

spider (rear suspension) of the driver.

The biggest problem with this approach is that spider

limiting behavior plays a hugely important role a

woofer's performance. Lead-wires that are attached or

woven into the spider material can alter the spider's

"stretching" behavior. The tinsel wire

naturally has less 'give' than the fabric

material of the spider leading to asymmetrical spider

behavior and non-uniform stress distribution around the

spider circumference. The wire attachment points can also

cause localized pulling and tearing forces at the

spider's excursion limits. As such, longevity becomes

a major concern and makes the woven-in design less than

ideal for very long-excursion designs.

While a traditional 'flying lead' design does not

compromise spider linearity or radial stability, it

creates its own challenges on a long-excursion woofer.

Managing the 'whipping' behavior of the wire and

making sure it does not contact the cone or spider is one

challenge. Another is ensuring that the leads do not

short one another or the frame of the woofer.

To overcome these issues, JL Audio's engineered

flying lead-wires work in conjunction with carefully

engineered entry and exit support structures molded into

the terminals and the voice coil collar. Some models also

feature jacketed lead-wires to further reduce the

likelihood of shorting and fatigue. The result is

flawless high-excursion lead-wire behavior, with

outstanding reliability and none of the compromises

inherent to a woven-in lead wire system. Building woofers

this way requires much more labor and parts complexity

than the simpler woven-in approach, but the payoff is in

reduced distortion, reduced mechanical noise and improved

reliability.

Tab-Ear Frame Design

This frame design feature facilitates mounting the

subwoofer driver in tight spaces.

By employing a tab-ear mounting system, the driver's

overall outside dimensions are reduced, permitting it to

be mounted in a space that is very similar to that

required by the next smaller round woofer frame.

Concentric Tube Suspension (U.S. Patent #5,734,132 &

#6,095,280)

JL Audio's patented Concentric Tube Suspension

technology delivers unprecedented excursion in a

low-profile woofer.

The biggest challenge in any low-profile woofer design is

to create enough mechanical clearance for the speaker to

generate enough excursion to meet its output and

low-frequency extension goals. Since these goals were

very ambitious in the development of JL Audio's low

profile woofers, achieving them required development of a

new suspension architecture.

JL Audio's patented solution employs a molded

structure which spans over the edge of the motor system,

supporting the spider on the outside of the motor's

boundaries and the large diameter voice coil on the

inside. The large diameter voice coil permits the magnet

to sit inside it, rather than surrounding the coil as is

typical in most woofers.

The concentric tube structure and the elimination of a

conventional top-plate helps JL Audio place the motor

system higher up into the cone body's space to

further compress depth, while still permitting excellent

mechanical excursion.

Precision Built in U.S.A.

JL Audio's Miramar, Florida loudspeaker production

facility is one of the most advanced in the world.

At a time when most audio products are built overseas, JL

Audio's commitment to in-house loudspeaker production

continues to grow. All W7's, W6's, TW5's,

TW3's, TW1's, W3v3's and some of JL

Audio's ZR products. JL Audio also build their Marine

Speaker Systems, Home Subwoofers, Stealthbox products and

the vast majority of their enclosed subwoofer systems in

Florida.

To pull this off in a competitive world market, JL

Audio's production engineering team has created one

of the world's most advanced loudspeaker assembly

facilities. This commitment to state-of-the-art

technology allows their highly skilled workforce to

efficiently build JL Audio products to extremely high

quality standards.

While it is also feasible to build good quality products

overseas (and JL Audio does build some of their products

in Europe and Asia), it can be challenging when the

product's technology is innovative or complex. Since

most of JL Audio's premium loudspeakers incorporate

proprietary, patented technologies requiring specific

assembly techniques, JL Audio prefers that the people who

design them have close access to the people manufacturing

them.

JL Audio - Ahead of the curve.

Features and Specifications:

- Amplified Subwoofer System with Single 12TW1-0.25

Subwoofer Driver, Built-In 400W Class D Amplifier, Black

Carpet - Sealed Enclosure

- Continuous Power Handling (RMS) - Built-in amplifier

400 W @ 0.25 Ohm

- System Nominal Impedance - 0.25 Ohm

- Input Voltage Range @ RCA Inputs - 70 mV - 1.40 V RMS

- Input Voltage Range @ High-Level Inputs - 280 mV -

5.4 V RMS

- Recommended Copper Power / Ground Wire Gauge - 8 AWG

wire

- Fuse Rating - 30 A (ATO or ATC)

- Enclosure Type - Slot-ported, Low-profile

- Finish - Black carpet

- Grille Included - Black Steel Mesh

- Filter Mode(s) - Low-Pass only

- Filter Slope(s) - 12 dB/octave

- Filter Frequency Range - 50 Hz - 200 Hz

- Output Polarity Switch - Yes

- Remote Subwoofer Level Control - Optional (RBC-1)

- UPC 0699440933353

- Color: Black

- Manufacturer's Limited Warranty - 2 Year(s)

- Sold: Each

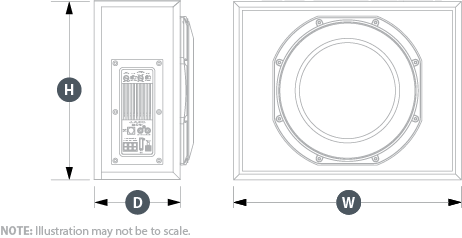

ACS112LG-TW1 - Physical Specifications

|

|

External Width (W)

|

21 in / 533 mm

|

|

External Height (H)

|

13.5 in / 343 mm

|

|

External Depth (D1)

|

6.625 in / 168 mm

|

|

Net Weight

|

29.2 lb / 13.24 kg

|

|

The ACS112LG-TW1

Product Manual

JL Audio (ACS112LG-TW1) - Single 12TW1 PowerWedge+ with

DCD Amplifier

Please Note:

- This Selection Is JL Audio (ACS112LG-TW1) ONLY.

- Manufacturer's product specifications,

packaging and limited warranties (if applicable) are

subject to change.

- Images are solely for illustrative purposes and may

reflect multiple items or multiple views of a single

item.

- This Item Is Sold: Each

Please sign our guest book.

Please sign our guest book. Join us on gab!The home of free speech online.

Join us on gab!The home of free speech online.